Double Column Machining Center

PV-3221

X:3200 / Y:2100 / Z:800 (mm)

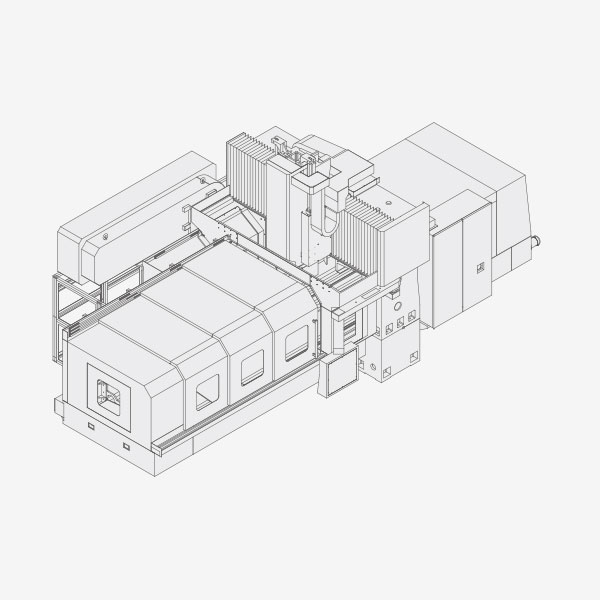

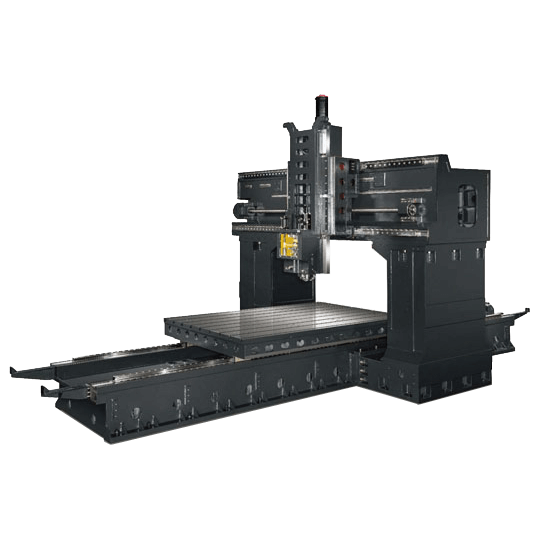

A Family of Double Column Machining Centers that retain Campro's traditional machine characteristics of Strong, Rigidity, and Precision, with sizes up to 5,200 mm(204.7'') x 2,600 mm (102.3") in travels. These machines offer the highest accuracies of any bridge mill on the market and can efficiently machine large parts due to their rigid design.

The PV-3221 Series features an extended X-axis with over 2 meters of oversized column, offering versatility and rigidity. The structure provides a wide range of options and customers can adopt different milling heads to finish larger workpieces, such as those used in the automobile and aerospace industries.

Feature

Combining stability and rigidity, it meets the user's needs for processing large workpieces and multiple processes.

Standard 25HP 6,000 rpm Gear-Head Spindle.

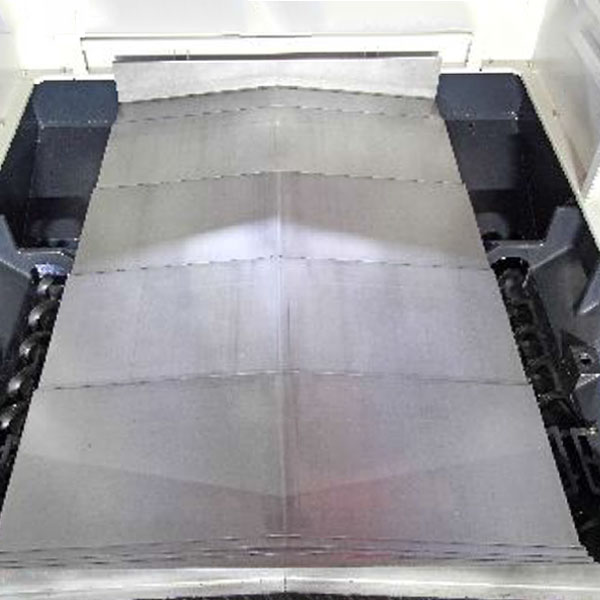

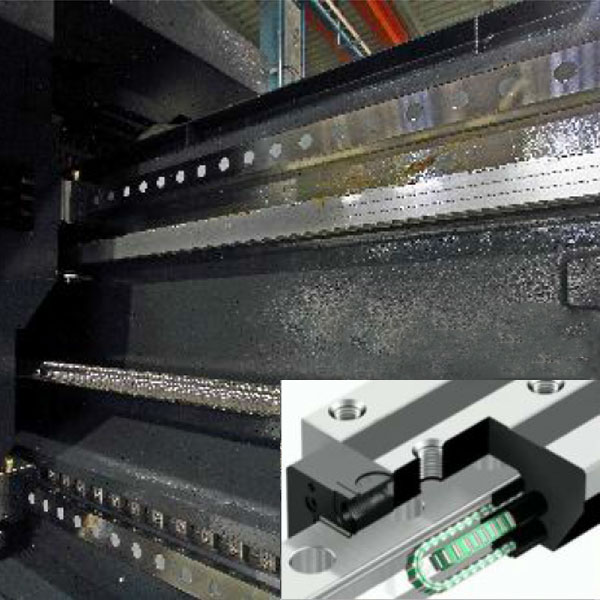

Extra heavy load roller linear guideways on X & Y axes increase rigidity in axial and lateral directions.

One-piece casting design in ram and gear box with box way on Z-axis provides excellent performance for heavy-duty cutting.

PV series comes with standard 32-tool #50 chain type ATC, the dual arm system ensure the stability during tool change.

Machine Specification

| Item | Unit | PV-3221 |

|---|---|---|

| Travel | ||

| X axis travel | mm (in) | 3,200 (125.9") |

| Y axis travel | mm (in) | 2,100 (82.6") |

| Z axis travel | mm (in) | 800 (31.4") OPT: 1,000 (39.3") |

| Distance between columns | mm (in) | 2,200 (86.6") |

| Spindle nose to table surface | mm (in) | 200~1,000 (7.8"~39.3") OPT: 250~1,250 (9.8"~49.2") |

| Table | ||

| Table dimension | mm (in) | 3,000 × 1,700 (118.1" x 66.9") |

| Max. loading weight | kg (lb) | 8,000 (17,636) |

| T-slots (W x No.) | mm (in) | 22 x 9 (0.86" x 9) |

| Spindle | ||

| Spindle speed | rpm | 6,000 rpm Gear-head spindle |

| Spindle motor | kW (HP) | 15 / 18.5 (25HP) |

| Spindle taper | type | 7/24 taper No.50 |

| Auto. Tool Change | ||

| Tool shank | type | BT-50 |

| Tool storage capacity (OPT) | pcs. | 32 (40 / 60) |

| Max. tool diameter | mm (in) | Ø125 (Ø4.9") |

| Max. tool diameter (Adjacent empty) | mm (in) | Ø215 (Ø8.4") |

| Max. tool length | mm (in) | 350 (13.7") |

| Max. tool weight | kg (lb) | 20 (44) |

| Feedrate | ||

| Rapid feedrate (X / Y / Z) | m (in) /min. | 12 / 15 / 15 (472.4 / 590.5 / 590.5) |

| Cutting feedrate | mm (in) /min. | 1~8,000 (314.9) |

| Others | ||

| Floor plan (W × D) | mm (in) | 8,800 × 5,000 (346" x 196") |

| Machine weight | kg (lb) | 35,000 (77,161) |

| Max. machine hight | mm (in) | 4,200 (165") |

| Air source | kg/cm2 (PSI) | 6~8 (85~113) |

| Power capacity | KVA | 40 |

Need Inquire ?

If you need more information or quotation about this product, Our sales representative will reply as soon as possible