Horizontal Machining Center

A vertical machining center (VMC) is a type of machining center where the spindle is oriented vertically. It is commonly used for milling, drilling, and tapping operations. On the other hand, a horizontal machining center (HMC) is a machining center with a horizontal spindle orientation. This design offers advantages for uninterrupted production work. Moreover, horizontal machine often features a two-pallet changer system, enabling efficient utilization of the machine's space. While machining is performed on one pallet, the other pallet can be loaded with new work, reducing downtime and improving operational efficiency.

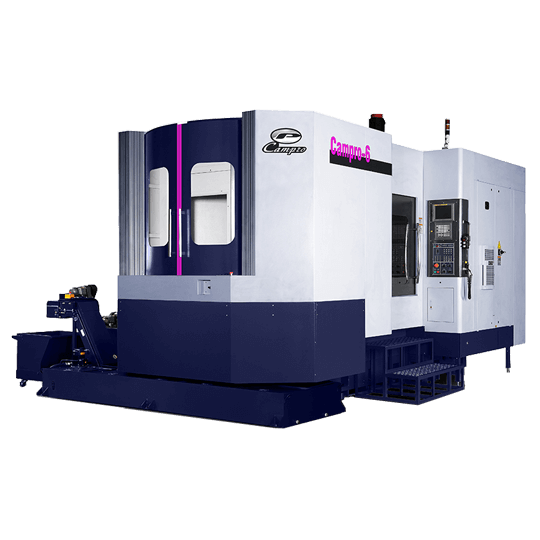

The Campro CNC Horizontal Machining Center, or HMC, is a highly efficient machine suitable for mass production of metal components. Campro offers HMCs with optional 2-pallet combined with B-axis rotary table Automatic Pallet Changer (APC). The one-to-one synchronized pallet change permits workpiece loading and unloading during machining to save waiting time and achieve 100% machining operation efficiency. The Campro HMCs are designed to meet the needs of aerospace, automotive, and die & mold industries.

In summary, a vertical machining center (VMC) has a vertically oriented spindle and is versatile for milling and various machining operations. On the other hand, a horizontal CNC machine features a horizontal spindle orientation, allows for efficient chip removal, and often incorporates a two-pallet changer system.

Applications: Aerospace, Automotive and Die & Mold

Campro Series

Need Inquire ?

If you need more information or quotation about this product, Our sales representative will reply as soon as possible