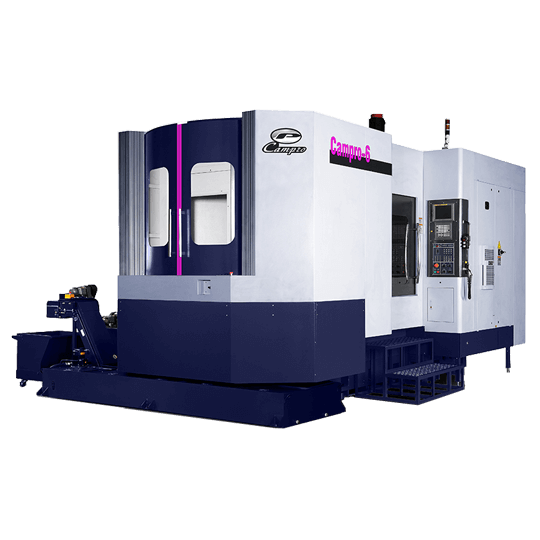

Horizontal Machining Center

CAMPRO 6

X:1000 / Y:850 / Z:950 (mm)

The Campro 6 CNC Horizontal Machining Center offers No. 50 taper on 6,000 rpm Gear Head spindle and also available on 10,000 rpm Built-in Motor spindle, with two-pallet changer integration and B-axis rotary table that are the best combination for high-volume production, the machine travels of 1,000 mm x 850 mm x 950 mm with dia. 630 mm table provides dia. 1,050mm x H 1,000 mm working range. The Campro 6 is ideal for large parts and tombstones metalworking applications.

Machine Specification

| Item | Unit | CAMRPO 6 |

|---|---|---|

| Travel | ||

| X axis travel | mm (in) | 1,000 (39.3") |

| Y axis travel | mm (in) | 850 (33.4") |

| Z axis travel | mm (in) | 950 (37.4") |

| Spindle nose to table center | mm (in) | 150~1,100 (5.9" ~ 43.3") |

| Spindle center to table surface | mm (in) | 100~950 (3.9" ~ 37.4") |

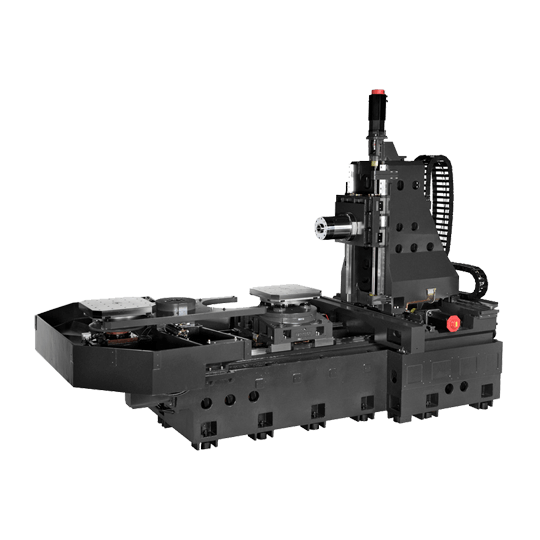

| Table | ||

| Table dimension | mm (in) | 630 × 630 (24.8" x 24.8") |

| Screw spec. | type | M16 × 2P |

| Index of pallet | degree | 1° |

| Max. working range | mm (in) | Ø1,050 × H1,000 (Ø41.3" x H39.3") |

| Max. loading weight | kg (lb) | 1,000 (2,204) |

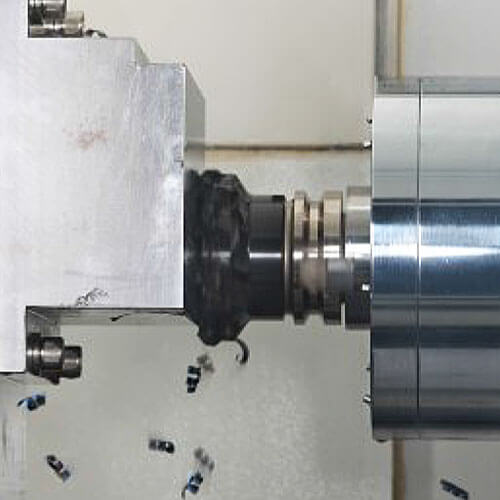

| Spindle | ||

| Spindle motor | kg (lb) | L: 15 / 22, H: 25 / 30 |

| Spindle speed | rpm | 10,000 |

| Spindle taper | type | 7/24 taper No.50 |

| Automatic Tool Changer | ||

| No. of tools | number | 40 |

| Max. tool weight | kg (lb) | 20 (44) |

| Max. tool length | mm (in) | 500 (19.6") |

| Max. tool diameter | mm (in) | Ø120 (Ø4.7") |

| Max. tool diameter (Adjacent empty) | mm (in) | Ø240 (Ø9.4") |

| Tool change time (Tool to Tool) | sec. | 3.5 |

| Tool change time (Chip to Chip) | sec. | 7 |

| Feedrate | ||

| Rapid feedrate (X/Y/Z) | m (in) /min | 36 / 36 / 36 (1,417.3 / 1,417.3 / 1,417.3) |

| Cutting feedrate | mm (in) /min | 10,000 (393.7) |

| Other | ||

| Floor plan (W×D) | mm (in) | 7,135 × 5,068 (280" x 199") |

| Machine weight | kg (lb) | 24,000 (52,910) |

| Max. machine hight | mm (in) | 3,550 (139") |

| Power capacity | KVA | 60 |

Need Inquire ?

If you need more information or quotation about this product, Our sales representative will reply as soon as possible