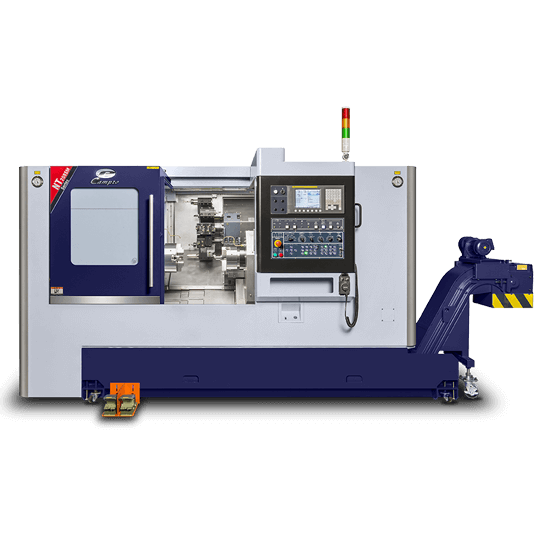

CNC Turning and Milling Center

NT-2510SY

X:210+20 / Y:100(±50) / Z:570 (mm)

The NT-2510SY 30° Slant-bed Box Way Turning & Milling Center is a cutting-edge CNC turn mill center machine that offers exceptional capabilities for precision machining. Equipped with the Y-axis, BMT Living Turret, and Sub-spindle, this advanced machine provides numerous advantages for various machining operations.

NT-2510SY is constructed with a one-piece 30° slant-bed design, incorporating advanced FEA and optimized 3D CAD techniques. This construction ensures superior rigidity, allowing for stable and reliable machining operations. Additionally, the Box Way design further enhances the machine's capability for heavy cutting, enabling efficient removal of material and maximizing productivity.

The Y-axis function on NT-2510SY enables off-center machining to accommodate multiple processes and reduces inaccuracies resulting from machining. The Real Y-axis allows for servo compensation, ensuring excellent positioning accuracy.

Unleash Precision and Efficiency with the CAMPRO CNC Turning and Milling Center. CAMPRO offers two configurations to choose from, both featuring the Y-axis function. One configuration includes a programmable tailstock, while the other includes a sub-spindle.

The NT-2510SY is equipped with a sub-spindle, which enables synchronized control with the main spindle, facilitating efficient primary and secondary turning operations.

This configuration is particularly advantageous for front and back-end turning applications, as it allows for the completion of both processes in a single machine setup. By integrating multiple machining operations, the NT-2510SY significantly enhances productivity and reduces production time.

Machine Specification

| Item | Unit | NT-2510SY |

|---|---|---|

| Capacity | ||

| Max. swing over bed | mm (in) | Ø680 (Ø26.7") |

| Max. swing over carriage | mm (in) | Ø460 (Ø18.1") |

| Max. turning length | mm (in) | 520 (20.4") |

| Max. turning diameter | mm (in) | Ø400 (Ø15.7") |

| Travel | ||

| X-axis | mm (in) | 210 + 20 (8.2" + 0.7") |

| Y-axis | mm (in) | 100 (±50) 3.9" (±1.9") |

| Z-axis | mm (in) | 630 (24.8") |

| Spindle | ||

| Spindle nose | type | A2-6 |

| Hydraulic chuck | inch | 8" |

| Hole through draw tube | mm (in) | Ø52 (Ø2.04") |

| Spindle motor | kW (HP) | 11 / 15 (20) |

| Spindle speed | rpm | 4,200 |

| Indexing of C-axis | degree | 0.001° |

| Sub Spindle | ||

| Spindle Nose | type | A2-5 |

| Hydraulic chuck | inch | 6" |

| Sub spindle motor | kW (HP) | 5.5 / 7.5 (10) |

| Sub spindle speed | rpm | 5,000 |

| Turret | ||

| Turret type | type | Servo |

| Nos. of turret | Nos. | 12-Station |

| Tool shank O.D. / I.D. | mm | □25 / Ø40 (BMT-55) |

| Servo motor | kW | 2.2 / 3.7 |

| Max. tool speed | rpm | 5,000 |

| Feedrate | ||

| Rapid feedrate (X / Y / Z) | m (in)/min. | 20 / 10 / 24 (787.4 / 393.7 /944.8) |

| Other | ||

| Floor plan (W x D x H) | mm (in) | 4,254 x 2,141x 2,381 (167" x 84" x 93") |

| Machine weight | kg (lb) | 4,700 (10,361) |

| Power capacity | KVA | 30 |

Need Inquire ?

If you need more information or quotation about this product, Our sales representative will reply as soon as possible