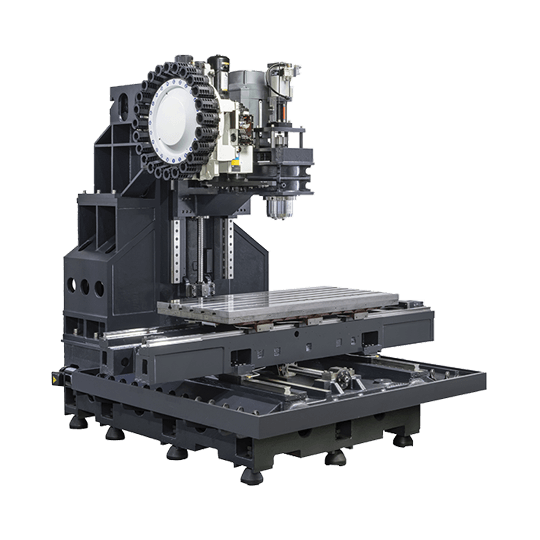

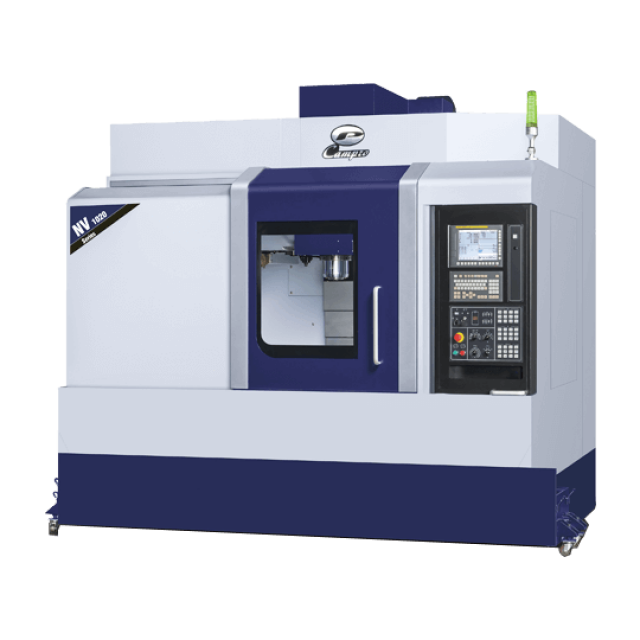

Vertical Machining Center

NV-1280

X:1280 / Y:650 / Z:630 (mm)

The NV-series smart vertical machining center has unique design on the loops and thermal symmetry structure of spindle which allows decreasing thermal deformation and increasing accuracy and stability.

The pleasant machine appearance combines aesthetics and ergonomics to get rid of the traditions, meets modern aesthetic needs. Campro ERP + IIoT provides Online Machine Monitoring, Machine Operating Monitoring, Machine Sensors & Trouble Shooting, Remote Control & Program Transmission, CPK Statistical Analysis for the factory of the future as Smart Factories - Factory to Factory and Global connection.

Machine Specification

| Item | Unit | NV-1280 |

|---|---|---|

| Travel | ||

| X axis travel | mm (in) | 1,280 (50.3") |

| Y axis travel | mm (in) | 650 (25.5") |

| Z axis travel | mm (in) | 630 (24.8") |

| Distance from spindle nose to table surface | mm (in) | 100~730 (3.9" ~ 28.7") |

| Distance from spindle center to column | mm (in) | 722 (28.4") |

| Table | ||

| Table dimension | mm (in) | 1,380 × 650 (54.3" x 25.5") |

| Max. loading weight | kg (lb) | 1,200 (2,645) |

| T-slots (W x No. x P) | mm (in) | 18 x 5 x 100 (0.7" x 5 x 3.9") |

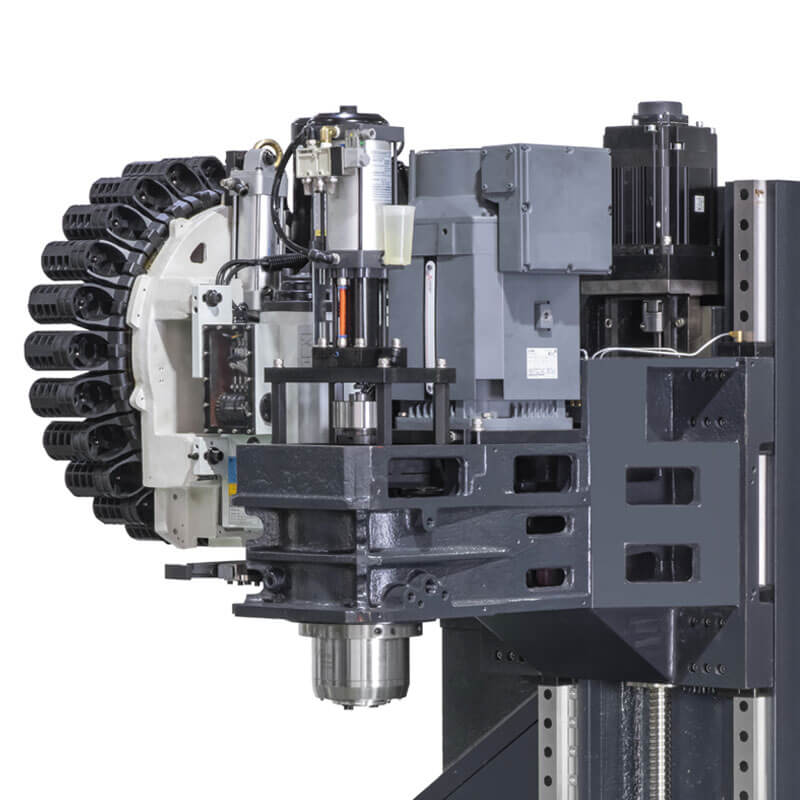

| Spindle | ||

| Spindle speed (OPT) | rpm | 10,000 (12,000 / 15,000) |

| Spindle motor | kW (HP) | 11 / 15 (20HP) |

| Spindle taper | type | 7/24 taper No.40 |

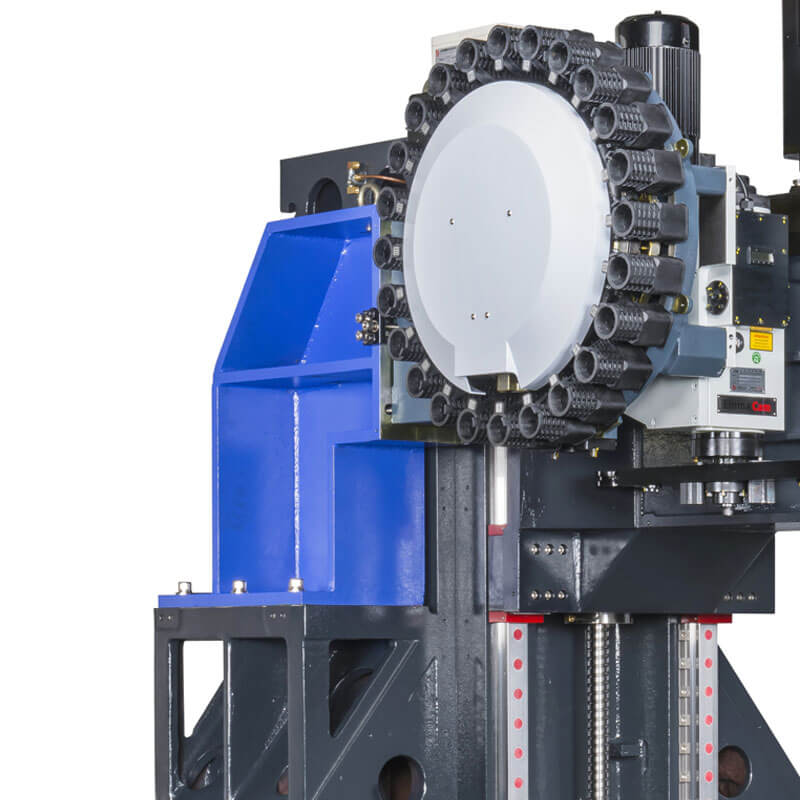

| Automatic Tool Changer | ||

| ATC type | type | Arm type |

| Tool shank | type | BT-40 |

| Pull stud | type | P-40T (45°) |

| Tool storage capacity (OPT) | pcs. | 24 (30 / 32 / 40) |

| Max. tool diameter | mm (in) | Ø80 (Ø3.1") |

| Max. tool diameter (Adjacent empty) | mm (in) | Ø150 (Ø5.9") |

| Max. tool length | mm (in) | 250 (9.8") |

| Max. tool weight | kg (lb) | 7 (15) |

| Tool change time (Tool to Tool) | sec. | 2.5 |

| Tool change time (Chip to Chip) | sec. | 7 |

| Feedrate | ||

| Rapid feedrate (X / Y / Z) | m (in) /min | 36 / 36 / 24 (1,417.3 / 1,417.3 / 994.8) |

| Cutting feedrate | mm (in) /min | 10,000 (393.7) |

| Other | ||

| Floor plan (W × D) | mm (in) | 3,750 × 2,500 (147" x 98") |

| Machine weight | kg (lb) | 8,500 (18,739) |

| Max. machine hight | mm (in) | 2,800 (110") |

| Air source | kg/cm2 (PSI) | 6~8 (85~113) |

| Power capacity | KVA | 25 |

Need Inquire ?

If you need more information or quotation about this product, Our sales representative will reply as soon as possible