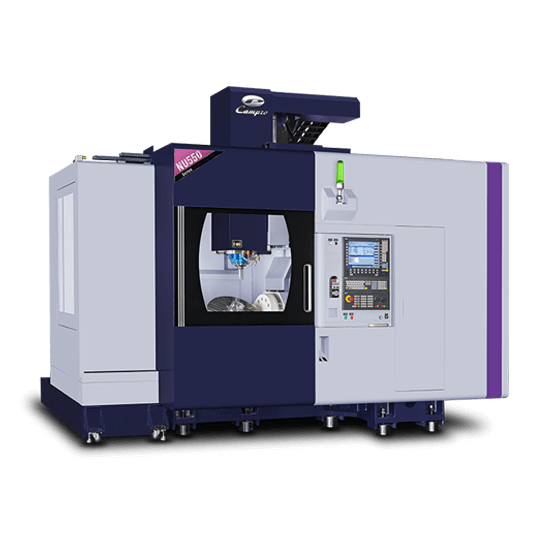

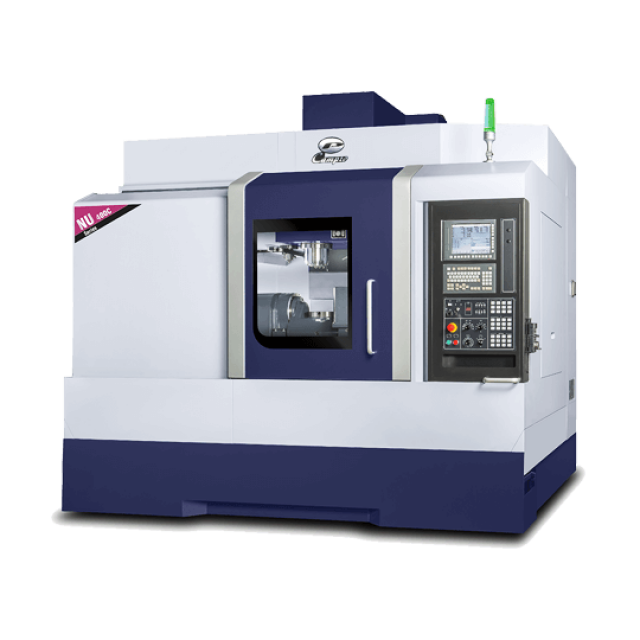

5 Axis Machining Center

NU 550

X:940 / Y:800 / Z:550 (mm)

NU Series 5 Axis Machining Centers are designed for highly efficient to meet the demands of multi-surface or complex shape machining. This advanced machine reduces processing time and enhances manufacturing quality.

With options for both 4+1 axis and 5-axis versions, it offers versatile capabilities for multi-surface machining. The 4+1 axis version enables 4-axis simultaneous motion with precise positioning on the remaining axis.

The 5-axis version takes it a step further with simultaneous control, allowing for tilted plane machining, cutter thin blade machining, and intricate shapes cutting.

By eliminating alignment errors, it improves component precision and extends cutting tool life.

Experience the power of the NU Series 5 Axis Machining Center for enhanced productivity and superior results in your manufacturing operations.

The Campro NU 550 Monoblock Column 5 Axis Machining Center, part of the NU Series, features a one-piece Monobloc column with tilting rotary table that gives workshops the versatility to machine complex components without the expense or large footprint of a swivel head machine.

Its unique bridge design allows for machining large workpieces in a smaller footprint while providing increased rigidity compared to a standard C-frame design.

With a state-of-the-art trunnion table for enhanced machining accuracies, the machine offers impressive specifications including a table dimension of Ø550 mm, A axis swiveling range of +30° ~ -120°, and a maximum workpiece dimension of Ø550x350 mm.

Additionally, it has a maximum loading weight of 300 kgf in the vertical direction and 250 kgf in the horizontal direction.

Machine Specification

| Item | Unit | NU 550 |

|---|---|---|

| Travel | ||

| X axis travel | mm (in) | 940 (37") |

| Y axis travel | mm (in) | 800 (31.4") |

| Z axis travel | mm (in) | 550 (21.6") |

| A axis swiveling range | deg. | +30°~-120° |

| C axis rotary range | deg. | 360° |

| Spindle nose to table surface | mm (in) | 80~630 (3.1" ~ 24.8") |

| Table | ||

| Table dimension | mm (in) | Ø550 (21.6") |

| Max. loading weight (V / H) | kg (lb) | 300 / 250 (661 / 551) |

| Spindle | ||

| Spindle motor | kW | 20 / 30 (40HP) |

| Spindle speed | rpm | 12,000 |

| Tool shank | type | BBT-40 |

| Automatic Tool Changer | ||

| No. of tools (OPT) | number | 32 (40 / 60) |

| Max. tool weight | kg (lb) | 7 (15) |

| Max. tool length | mm (in) | 250 (9.8") |

| Max. tool diameter | mm (in) | Ø75 (Ø2.9") |

| Max. tool diameter (Adjacent empty) | mm (in) | Ø127 (Ø5") |

| Feedrate | ||

| Rapid feedrate (X / Y / Z) | m (in)/min. | 36 / 36 / 30 (1,417.3 / 1,417.3 / 1,181.1) |

| Rapid feedrate (A / C) | rpm | 11.1 / 16.6 |

| Other | ||

| Floor plan (W × D) | mm (in) | 4,100 × 3,650 (161" x 143") |

| Machine weight | kg (lb) | 11,000 (24,250) |

| Max. machine hight | mm (in) | 3,300 (129") |

| Power capacity | KVA | 50 |

Need Inquire ?

If you need more information or quotation about this product, Our sales representative will reply as soon as possible